- uses electrical energy to produce mechanical energy, through the interaction of magnetic fieldscurrent-carrying conductors. The reverse process, producing electrical energy from mechanical energy, is accomplished by a generator or dynamo. Traction motors used on vehicles often perform both tasks. Many types of electric motors can be run as generators, and vice versa.

- found in applications as diverse as industrial fans, blowers and pumps, machine tools, household appliances, power tools, and disk drives. They may be powered by direct current (for example a battery powered portable device or motor vehicle), or by alternating current from a central electrical distribution grid. The smallest motors may be found in electric wristwatches. Medium-size motors of highly standardized dimensions and characteristics provide convenient mechanical power for industrial uses. The very largest electric motors are used for propulsion of large ships, and for such purposes as pipeline compressors, with ratings in the millions of watts. Electric motors may be classified by the source of electric power, by their internal construction, and by their application.

The physical principle of production of mechanical force by the interactions of an electric current and a magnetic field was known as early as 1821. Electric motors of increasing efficiency were constructed throughout the 19th century, but commercial exploitation of electric motors on a large scale required efficient electrical generators and electrical distribution networks.

By convention, electric engine refers to a railroad electric locomotive, rather than an electric motor.

its principle

The conversion of electrical energy into mechanical energy by electromagnetic means was demonstrated by the British scientist Michael Faraday in 1821. A free-hanging wire was dipped into a pool of mercury, on which a permanent magnet was placed. When a current was passed through the wire, the wire rotated around the magnet, showing that the current gave rise to a circular magnetic field around the wire.[2] This motor is often demonstrated in school physics classes, but brine (salt water) is sometimes used in place of the toxic mercury. This is the simplest form of a class of devices called homopolar motors. A later refinement is the Barlow's Wheel. These were demonstration devices only, unsuited to practical applications due to their primitive construction.

Comparison of motor types

| Type | Advantages | Disadvantages | Typical Application | Typical Drive |

|---|---|---|---|---|

| AC Induction (Shaded Pole) | Least expensive Long life high power | Rotation slips from frequency Low starting torque | Fans | Uni/Poly-phase AC |

| AC Induction (split-phase capacitor) | High power high starting torque | Rotation slips from frequency | Appliances | Uni/Poly-phase AC |

| AC Synchronous | Rotation in-sync with freq long-life (alternator) | More expensive | Industrial motors Clocks Audio turntables tape drives | Uni/Poly-phase AC |

| Stepper DC | Precision positioning High holding torque | Requires a controller | Positioning in printers and floppy drives | DC |

| Brushless DC | Long lifespan low maintenance High efficiency | High initial cost Requires a controller | Hard drives CD/DVD players electric vehicles | DC |

| Brushed DC | Low initial cost Simple speed control | High maintenance (brushes) Low lifespan | Treadmill exercisers automotive starters | Direct DC or PWM |

| Pancake DC | Compact design Simple speed control | Medium cost Medium lifespan | Office Equip Fans/Pumps | Direct DC or PWM |

Servo motor

A servomechanism, or servo is an automatic device that uses error-sensing feedback to correct the performance of a mechanism. The term correctly applies only to systems where the feedback or error-correction signals help control mechanical position or other parameters. For example, an automotive power window control is not a servomechanism, as there is no automatic feedback which controls position—the operator does this by observation. By contrast the car's cruise control uses closed loop feedback, which classifies it as a servomechanism.

Synchronous electric motor

A synchronous electric motor is an AC motor distinguished by a rotor spinning with coils passing magnets at the same rate as the alternating current and resulting magnetic field which drives it. Another way of saying this is that it has zero slip under usual operating conditions. Contrast this with an induction motor, which must slip to produce torque. A synchronous motor is like an induction motor except the rotor is excited by a DC field. Slip rings and brushes are used to conduct current to rotor. The rotor poles connect to each other and move at the same speed hence the name synchronous motor.

Induction motor

An induction motor (IM) is a type of asynchronous AC motor where power is supplied to the rotating device by means of electromagnetic induction. Another commonly used name is squirrel cage motor because the rotor bars with short circuit rings resemble a squirrel cage (hamster wheel). An electric motor converts electrical power to mechanical power in its rotor (rotating part). There are several ways to supply power to the rotor. In a DC motor this power is supplied to the armature directly from a DC source, while in an induction motor this power is induced in the rotating device. An induction motor is sometimes called a rotating transformer because the stator (stationary part) is essentially the primary side of the transformer and the rotor (rotating part) is the secondary side. Induction motors are widely used, especially polyphase induction motors, which are frequently used in industrial drives.

Electrostatic motor (capacitor motor)

An electrostatic motor or capacitor motor is a type of electric motor based on the attraction and repulsion of electric charge. Usually, electrostatic motors are the dual of conventional coil-based motors. They typically require a high voltage power supply, although very small motors employ lower voltages. Conventional electric motors instead employ magnetic attraction and repulsion, and require high current at low voltages. In the 1750s, the first electrostatic motors were developed by Benjamin Franklin and Andrew Gordon. Today the electrostatic motor finds frequent use in micro-mechanical (MEMS) systems where their drive voltages are below 100 volts, and where moving, charged plates are far easier to fabricate than coils and iron cores. Also, the molecular machinery which runs living cells is often based on linear and rotary electrostatic motors.

DC Motors

A DC motor is designed to run on DC electric power. Two examples of pure DC designs are Michael Faraday's homopolar motor (which is uncommon), and the ball bearing motor, which is (so far) a novelty. By far the most common DC motor types are the brushed and brushless types, which use internal and external commutation respectively to create an oscillating AC current from the DC source—so they are not purely DC machines in a strict sense.

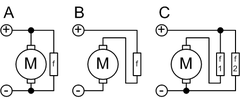

There are five types of brushed DC motor:

A. DC shunt wound motor

B. DC series wound motor

C. DC compound motor (two configurations):

- Cumulative compound

- Differentially compounded

D. Permanent Magnet DC Motor (not shown)

E. Separately-excited (sepex) (not shown).

AC motor consists of two parts:

- An outside stationary stator having coils supplied with AC current to produce a rotating magnetic field, and;

- An inside rotor attached to the output shaft that is given a torque by the rotating field.

2 comments:

much obliged for the tips and information..i truly value it.. camping generators

Thanks for sharing valuable and rare information with us through this amazing blog

Electrical Panel Boards Suppliers and dealers

Post a Comment